With three batches bottled, and either carbonating or conditioning, it must be time to brew again.

I decided to create my own recipe for a Cascadian or Northwest style organic Black IPA. My favorites include

21st Amendment Back in Black on the light end, through

HUB Secession and

Stone Sublimely Self Righteous in the middle, to

Deschutes Hop in the Dark and

Alaskan Double Black IPA on the high gravity end of things. And not to forget

Pizza Port (Carlsbad) Big Black Poochie that is off the charts entirely.

In order to come up with a brew that I hope will blend the qualities I like best in these Black IPA style beers, I figured a good place to start would be to compare and combine the detailed clone recipes that ran recently in Brew Your Own Magazine Vol. 16, No. 4, and Zymurgy Magazine Vol. 33, No. 4.

Immediately, one realizes the clone recipes, while similar in output, are all totally different in ingredients and brew techniques. A few web searches turn up some ideas for the Stone and Deschutes examples, but in percentages rather than amounts. So, I take the Secession clone recipe from Brew as a base, then begin stretching and combining it with the information I can find on the

homebrew forums for the others, along with some guesswork about substitutions of available organic grains, hops, and yeasts.

A Black IPA has specific targets for the style in ABV, IBUs, color, flavor, etc. And once I formulated my first draft of a recipe, I checked and adjusted it as closely as is possible to the guidelines, with

The Beer Recipator online tool. I think the brew I first came up with would be closer to a whiskey than a beer - it was that heavy duty!

The great thing about the Recipator, and I'm sure other

Beer Tools, is that you can tweak your recipes in many different directions to get the projected outcome to fit within style guidelines. Or, I suppose, you could also use the guidelines as merely a starting point for more individually expressive brews.

Since Cascadian (Black) IPA is a new style, you have to speculate about some of the target outcomes, but I think it has allowed me to come up with a recipe that will at least be close to the known style guidelines, and a starting point for building my ideal beer in future batches. I'm using a half pound each of flaked oats for smoothness, which I will roast before steeping, and flaked rye for aroma.

The Recipator lets you output a recipe formatted for sharing, like what you see below. Pretty slick.

Beer: Northern Lights Cascadian IPA

Style: India Pale Ale

Type: Extract w/grain

Size: 5 gallons

OG: | 1.062 | FG: | 1.018 |

Alcohol: | 5.4% v/v (4.2% w/w) |

Grain: |

1.0 lb. Briess Organic Black Malt (500 ºL) cold steep 8.0 oz Weyermann Organic Carafa® 2 (dark chocolate) cold steep ___________________________________________________

1 lb. Gambrinus Organic Pilsner Malt

1 lb. 1.0 lb. Weyermann Pilsner Malt

8 oz. Great Western Organic Munich Malt 8 oz. Great Western Organic Crystal 60 Malt (60 ºL)

4.0 oz Weyermann Organic Carafa® 2 (dark chocolate)

8 oz. Flaked oats

8 oz. Flaked rye |

Boil: | 60 minutes | SG 1.060 | 5.5 gallons |

6 lb. Light malt extract 8 oz. Cane sugar |

Hops: | 1 oz. American Bravo Organic Whole Hops (13.5% AA, 60 min.) .5 oz. Centennial (10.5% AA, 30 min.) .5 oz. American Summit Organic Whole Hops (13.5% AA, 30 min.)

1.0 oz. New Zealand Cascade Pellet Hops (5 mins) 1.0 oz. American Summit Pellet Hops (5 mins) .5 oz. New Zealand Cascade Pellet Hops (dry hop) 1 oz. American Summit Pellet Hops (dry hop) |

Step by Step Partial Mash Brewing Instructions:

Make a yeast starter from the White Labs London Ale liquid yeast three days prior to pitching.

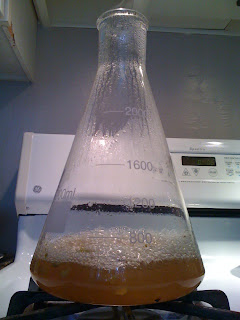

Steep the crushed grain in 2.0 gallons of water at 152 ºF for 30 to 60 minutes. Remove grains from the wort and sparge with 2.0 quarts of 170º water. Place mash in 7.5 gallon boil kettle and add 4.0 gallons of 210º water to make 6.5 gallons and bring to near boiling. Turn off heat and add the liquid malt extract and cane sugar. Boil for 60 minutes. While boiling, add the hops, Irish moss, and yeast nutrient as per the schedule. Cool wort to 68º and transfer to sanitized bottling bucket or primary fermenter. Top off with cooled water to 5.0 gallons if necessary.

Pitch your yeast and aerate the wort heavily. Hold at 68 ºF for 7 days or until fermentation subsides.

When the primary fermentation is complete, rack beer to a carboy, avoiding any splashing to prevent aerating the beer and add the dry hops. Remove dry hops after 7 days then bottle or keg. Allow the beer to carbonate for one week at room temperature, then condition for 2 weeks at 50 ºF and enjoy your Northern Lights Cascadian IPA.